1. Clear and Clean Assembly Structure:The assembly structure in TCEng and Master Engineering Plan are always corresponding; Each work pack owner is responsible to keep the subassembly clean.

2. No suppressed Features when saving parts: Suppressed features will lead to corrupt 3D models. Always keep in mind that another team member has to understand the feature tree of a NX model;

3. Work on TCEng not native: The NX data is always available for the whole team;

4. Features well organized by Layer settings: Setting layers helps to keep the overview within a solid. Layer categories are defined within NX seedpart for Siemens BT.

5. Versions are built up by creating revisions: Different design variant of the same parts will be created by using revisions within TCEng;

6. Set the right Reference Sets: Reference sets define what will be displayed on a upper level in the assembly structure; It is a must to set the 3D-Model which will be displayed in the assembly or on the drawing on reference set called “solid”.

7. Use Speaking 7 Billion Numbering System: Part numbers used within products are created with speaking 7 billion numbers. For other items like used in test equipment use nonspeaking 8 billion numbers. Do not use PEK-numbers.

8. Work Tracking: Workpack owners always track running issues regarding parts within a work tracking list.

9. Dimension on drawings MUST be assotiative: It is forbidden to change dimension on drawing manually by annotation editor.

10. Follow design rules defined in CHECKDRAW: Checkdraw is available from your superuser.

1. Clear and Clean Assembly Structure:The assembly structure in TCEng and Master Engineering Plan are always corresponding; Each work pack owner is responsible to keep the subassembly clean.

明確和清晰的裝配結構:在Teamcenter Engineering里的裝配結構要和主工程計劃里的始終一致,每個工作任務的所有者負責保持裝配的清晰。

這個是與工作環境有關係,研發過程中除了在Teamcenter Engineering里維護了裝配結構外,還需要在本地項目的文檔里建立裝配結構,這一條的意思就是要保持二者的一致。

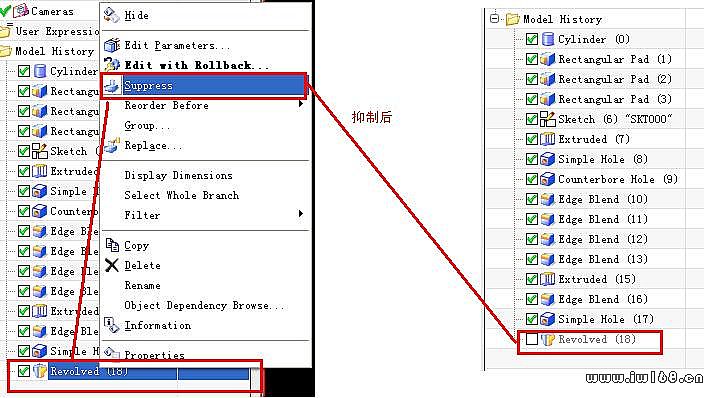

2. No suppressed Features when saving parts: Suppressed features will lead to corrupt 3D models. Always keep in mind that another team member has to understand the feature tree of a NX model;

保存零件時不準有抑制的特徵:抑制的特徵會導致3D模型混亂。始終記住另一個團隊的成員需要理解NX模型的特徵樹。

如果在建模時有抑制的特徵,會導致其他人看圖時不明白這個特徵是要還是不要,不利於對模型的理解,如果這個特徵不需要了,就直接刪除就可以了。

3. Work on TCEng not native: The NX data is always available for the whole team;

基於Teamcenter Engineering工作而不是本地工作;這樣整個團隊都能獲取NX數據。

這也是PDM或者PLM軟體的好處,便於數據的共享。

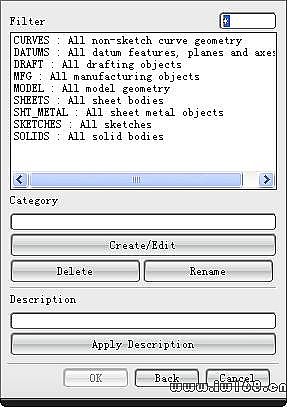

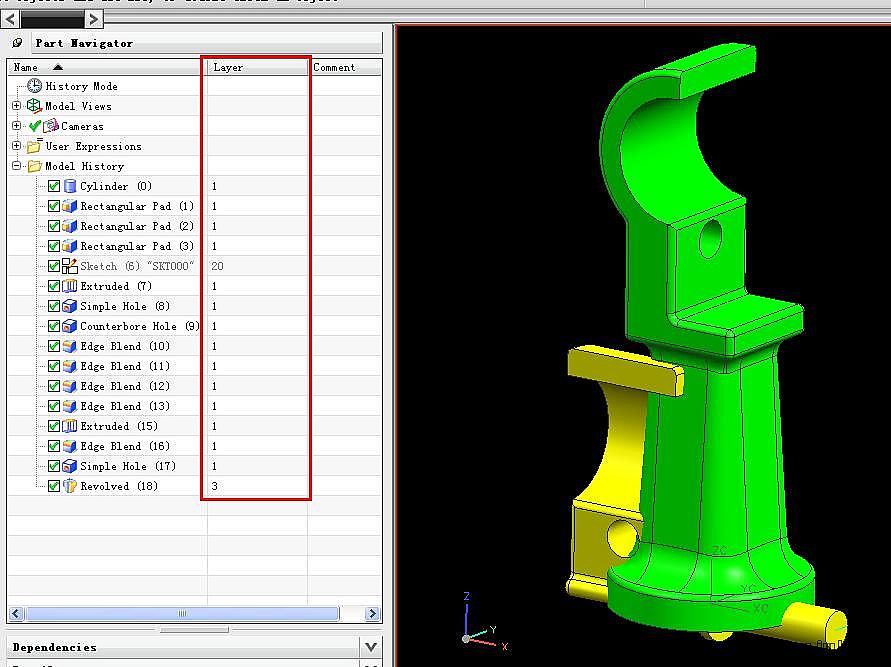

4. Features well organized by Layer settings: Setting layers helps to keep the overview within a solid. Layer categories are defined within NX seedpart for Siemens BT.

特徵通過層設置進行組織:層設置便於通過實體來總攬,通過定義NX種子文件設置適用於整個集團的層分類。

以下是NX自帶的層設置

在該外企里定義了自己的企業標準,每一類層包含哪些,都有具體的含義,當工程師建完模型后,要進行特徵組織,把相應的特徵放到相應的層里。這樣可以通過調整層的顯示,讓模型只顯示實體,而不顯示草圖、基準特徵等,便於模型的理解。

5. Versions are built up by creating revisions: Different design variant of the same parts will be created by using revisions within TCEng;

通過在Teamcenter Engineering里建立修訂版來控制版本:使用Teamcenter Engineering里的修訂版來建立同類零件的不同設計想法

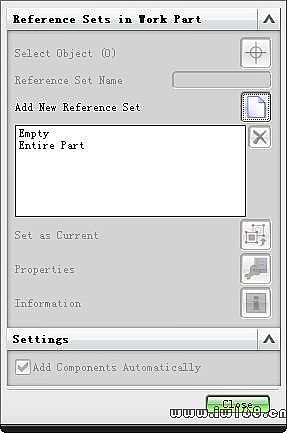

6. Set the right Reference Sets: Reference sets define what will be displayed on a upper level in the assembly structure; It is a must to set the 3D-Model which will be displayed in the assembly or on the drawing on reference set called “solid”.

設置正確的引用集:引用集定義了在裝配結構的上一層中零件的顯示方式。在裝配和工程圖上顯示的3D模型必須設置為"Solid"引用集。

以下是NX自帶的引用集

該公司設置了自己的引用集標準,並且要求設置為"Solid",其實現原理跟第4條一致

7. Use Speaking 7 Billion Numbering System: Part numbers used within products are created with speaking 7 billion numbers. For other items like used in test equipment use nonspeaking 8 billion numbers. Do not use PEK-numbers.

這是企業編碼的要求,只解釋下 speaking 和nonspeaking 的區別,speaking的編碼是結構化的編碼,每一位表示具體的含義,non的編碼則是一個大流水,沒有具體的含義。

這是在使用NX/Teamcenter時的要求

工作跟蹤:工作任務的所有者始終在工作跟蹤列表裡跟蹤零件存在的問題。

這是企業研發流程的需要,Teamcenter只存了3D模型和二維工程圖,零件中存在的問題通過項目管理的work tracking list來進行跟蹤,並要求工程師保持二者的一致。

9. Dimension on drawings MUST be assotiative: It is forbidden to change dimension on drawing manually by annotation editor.

工程圖上的尺寸標註必須關聯:禁止通過“註釋”來修改工程圖上的尺寸標註。

這樣可以保持3D模型和工程圖的一致,當3D模型做了修改時,工程圖的數據會自動更新。同時也便於其他人理解工程圖。

10. Follow design rules defined in CHECKDRAW: Checkdraw is available from your superuser.

遵守CHECKDRAW里的設計要求:可以從superuser那獲取CHECKDRAW文檔。

CHECKDRAW是一個企業規範,定義了詳細的作圖原則,圖紙模板,以及NX/Teamcenter的操作規範。

superuser是部門的NX/Teamcenter負責人,因為superuser更了解業務。在工程師有問題的時候,先向superuser反應,如果superuser解決不了,再由superuser向公司的admin反應,admin解決不了會向總部的支持團隊反應,總部的支持團隊也解決不了的時候,再向軟體的供應商反應。